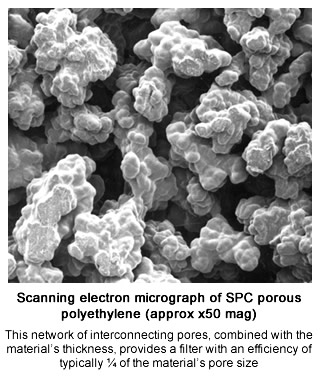

SPC Technologies porous plastic is a semi-rigid, open-cell porous material made by a process known as sintering. The inter-connecting pores mean that the material is permeable to fluids, the permeability being adjusted as required by controlling the pore size. This permeability means that the material works as a filter, the filtration capacity also controlled by the size of the pores. Typically, the proportion of the material which is open is 30-40% (known as the void volume) although materials may be produced with void volumes as high as 60% for special applications.

Our porous components are available in sheets, rolls, discs and custom designed mouldings. We offer a range of standard sheet products made from porous polyethylene, as well as the facility to develop a custom product to meet the needs of your particular application. Sheet products are available in thicknesses from 0.6mm to 6mm, and pore sizes from 20 microns to 250 microns. To give an idea of the range of materials, available pore sizes, and the effect on permeability please view the table of standard sheet products. Most of these materials are also available as mouldings. The material typically filters out particles 3-4 times smaller than the pore size (depending on thickness).

Our porous components are available in sheets, rolls, discs and custom designed mouldings. We offer a range of standard sheet products made from porous polyethylene, as well as the facility to develop a custom product to meet the needs of your particular application. Sheet products are available in thicknesses from 0.6mm to 6mm, and pore sizes from 20 microns to 250 microns. To give an idea of the range of materials, available pore sizes, and the effect on permeability please view the table of standard sheet products. Most of these materials are also available as mouldings. The material typically filters out particles 3-4 times smaller than the pore size (depending on thickness).

SPC Technologies can produce porous plastics from a variety of polymers, and are able to control various properties within any particular polymer. Most of our products are manufactured using the polyolefins (polyethylene & polypropylene), which provide the most cost-effective solution for the majority of applications. These may be treated to be self-sealing (in the presence of water) or hydrophilic and are available in a range of pore sizes and permeabilities. Our products may also be pigmented to provide a choice of colours.

Most of our products can be produced from polymers with FDA and Pharmacopoeia approvals. If your application requires particular levels of certification, please specify this and we can ensure that the appropriate materials are selected right from the beginning of the project.

SPC porous plastic is readily machinable and can be easily welded; for more detailed information, please contact our engineering staff. The material's inherent flexibility makes it particularly suitable for push fitting into component parts of various materials to provide an effective and reliable seal. Bi-component materials may also be produced, combining the properties of two different porous materials within one sheet product in two separate layers.

All of our products are manufactured in the UK under an ISO 9001:2015 accredited quality system.